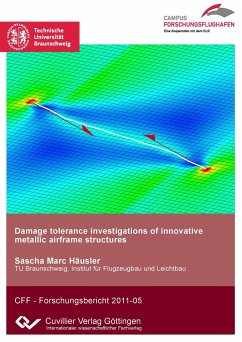

The continuously expanding commercial air traffic of the last decades steadily increased the demand for highly efficient aircraft which offer extended operation times while reducing costs and environmental impact at the same time. The associated design requirements for reduced structural weight and improved fatigue life represent the major challenges for todays aircraft structures and have significantly intensified the competition between metallic and composite airframe applications. New metallic design concepts try to face this competition by combining latest materials and innovative manufacturing methods, like high speed machining, laser beam welding or friction stir welding, which allows for possible savings with respect to structural weight and manufacturing costs. However, due to their integral characteristics, the damage tolerance behaviour of these new designs is generally inferior to the common differential design. Reliable estimations on the fatigue life of integrally stiffened structures consequently necessitate assessment methodologies that are capable to include additional manufacturing influences and offer numerical efficiency in order to be practical for parametric studies during airframe design. Therefore, the development and enhancement of simulation methods for efficient and reliable evaluation of cracks and crack growth represents the main objective of this thesis. Two simulation methods are implemented and investigated for this purpose, that are based on different approaches and intended for distinct applications. One method is based on analytical stress function expressions and enables a very efficient evaluation of the complete fatigue crack growth life of cracked airframe structures. The proposed approach in this context is generally based on plane assumptions and limited to pure mode I crack loading. In order to be able to additionally consider crack turning under mixed mode loading, a second simulation method is presented which implements an extended finite element framework for a mesh independent representation of cracks in two dimensions. The additional combination with the material force concept, as alternative crack state parameter, allows for automated simulations of crack growth under mixed mode loading without any need for remeshing operations. Both simulation methods are validated based on different crack configurations and are applied for crack growth investigations of varying configurations of integrally stiffened panels under pure mode I and mixed mode loading conditions. In this context, a special focus is set on the influences of additional internal stresses that follow either from the applied manufacturing processes or an intentional prestressing of the stiffeners. Despite the general limitation to plane considerations, the proposed methods show a good accordance with experimental, theoretical and alternative numerical results. This demonstrates their capabilities to simulate fatigue crack growth and crack turning in integrally stiffened airframe structures and motivates further research with respect to a possible extension to three-dimensional problems.