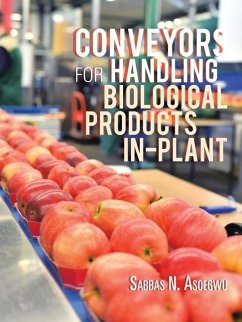

This book CONVEYORS FOR HANDLING BIOLOGICAL PRODUCTS IN-PLANT provides an in-depth approach to the fundamentals for the design of conveyors used in agricultural processing industries. It is written for agricultural engineering graduates and undergraduates as well as others in tertiary institutions interested in material handling equipment design. It is an eminently useful book for practicing engineers, designers and research workers as well as technicians and technologists. The conveyors covered in the book include belt, bucket, chain, gravity roller, hydraulic and pneumatic, screw and shaking conveyors as well as fans and blowers. The book approached the design and selection of conveyors by calculating their throughput capacities, the forces acting on them and the power requirement of each conveyor, with the hope that whoever uses the book must have attained an appropriate level of Mathematics and Physics to come to terms with the many mathematical equations used in the book. The design approach took into consideration the properties of the materials to be conveyed as well as those of the conveyors to be selected and used as a rational basis for the design. The book classified conveyors, showed the various factors to be considered when selecting conveyors and gave the general theory of conveyors before going into the design properly. The maintenance procedures for the traction-type conveyors were given. At the end of each chapter, worked examples, review questions and sample problems were given to enable the reader come to grips with the subject matter.