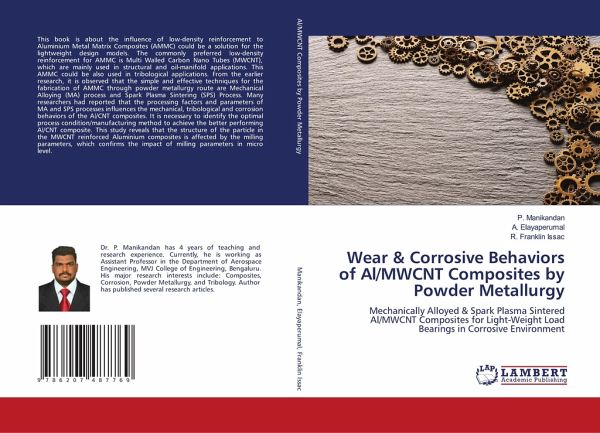

Wear & Corrosive Behaviors of Al/MWCNT Composites by Powder Metallurgy

Mechanically Alloyed & Spark Plasma Sintered Al/MWCNT Composites for Light-Weight Load Bearings in Corrosive Environment

Versandkostenfrei!

Versandfertig in 6-10 Tagen

45,99 €

inkl. MwSt.

PAYBACK Punkte

23 °P sammeln!

This book is about the influence of low-density reinforcement to Aluminium Metal Matrix Composites (AMMC) could be a solution for the lightweight design models. The commonly preferred low-density reinforcement for AMMC is Multi Walled Carbon Nano Tubes (MWCNT), which are mainly used in structural and oil-manifold applications. This AMMC could be also used in tribological applications. From the earlier research, it is observed that the simple and effective techniques for the fabrication of AMMC through powder metallurgy route are Mechanical Alloying (MA) process and Spark Plasma Sintering (SPS)...

This book is about the influence of low-density reinforcement to Aluminium Metal Matrix Composites (AMMC) could be a solution for the lightweight design models. The commonly preferred low-density reinforcement for AMMC is Multi Walled Carbon Nano Tubes (MWCNT), which are mainly used in structural and oil-manifold applications. This AMMC could be also used in tribological applications. From the earlier research, it is observed that the simple and effective techniques for the fabrication of AMMC through powder metallurgy route are Mechanical Alloying (MA) process and Spark Plasma Sintering (SPS) Process. Many researchers had reported that the processing factors and parameters of MA and SPS processes influences the mechanical, tribological and corrosion behaviors of the Al/CNT composites. It is necessary to identify the optimal process condition/manufacturing method to achieve the better performing Al/CNT composite. This study reveals that the structure of the particle in the MWCNT reinforced Aluminium composites is affected by the milling parameters, which confirms the impact of milling parameters in micro level.