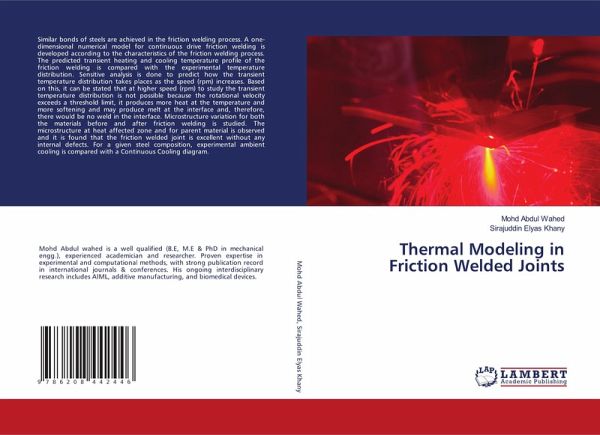

Thermal Modeling in Friction Welded Joints

Versandkostenfrei!

Versandfertig in 6-10 Tagen

40,99 €

inkl. MwSt.

PAYBACK Punkte

20 °P sammeln!

Similar bonds of steels are achieved in the friction welding process. A one-dimensional numerical model for continuous drive friction welding is developed according to the characteristics of the friction welding process. The predicted transient heating and cooling temperature profile of the friction welding is compared with the experimental temperature distribution. Sensitive analysis is done to predict how the transient temperature distribution takes places as the speed (rpm) increases. Based on this, it can be stated that at higher speed (rpm) to study the transient temperature distribution ...

Similar bonds of steels are achieved in the friction welding process. A one-dimensional numerical model for continuous drive friction welding is developed according to the characteristics of the friction welding process. The predicted transient heating and cooling temperature profile of the friction welding is compared with the experimental temperature distribution. Sensitive analysis is done to predict how the transient temperature distribution takes places as the speed (rpm) increases. Based on this, it can be stated that at higher speed (rpm) to study the transient temperature distribution is not possible because the rotational velocity exceeds a threshold limit, it produces more heat at the temperature and more softening and may produce melt at the interface and, therefore, there would be no weld in the interface. Microstructure variation for both the materials before and after friction welding is studied. The microstructure at heat affected zone and for parent material is observed and it is found that the friction welded joint is excellent without any internal defects. For a given steel composition, experimental ambient cooling is compared with a Continuous Cooling diagram.