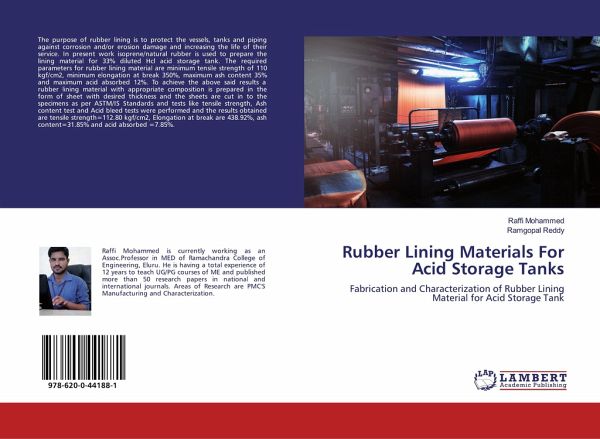

Rubber Lining Materials For Acid Storage Tanks

Fabrication and Characterization of Rubber Lining Material for Acid Storage Tank

Versandkostenfrei!

Versandfertig in 1-2 Wochen

26,99 €

inkl. MwSt.

PAYBACK Punkte

13 °P sammeln!

The purpose of rubber lining is to protect the vessels, tanks and piping against corrosion and/or erosion damage and increasing the life of their service. In present work isoprene/natural rubber is used to prepare the lining material for 33% diluted Hcl acid storage tank. The required parameters for rubber lining material are minimum tensile strength of 110 kgf/cm2, minimum elongation at break 350%, maximum ash content 35% and maximum acid absorbed 12%. To achieve the above said results a rubber lining material with appropriate composition is prepared in the form of sheet with desired thicknes...

The purpose of rubber lining is to protect the vessels, tanks and piping against corrosion and/or erosion damage and increasing the life of their service. In present work isoprene/natural rubber is used to prepare the lining material for 33% diluted Hcl acid storage tank. The required parameters for rubber lining material are minimum tensile strength of 110 kgf/cm2, minimum elongation at break 350%, maximum ash content 35% and maximum acid absorbed 12%. To achieve the above said results a rubber lining material with appropriate composition is prepared in the form of sheet with desired thickness and the sheets are cut in to the specimens as per ASTM/IS Standards and tests like tensile strength, Ash content test and Acid bleed tests were performed and the results obtained are tensile strength=112.80 kgf/cm2, Elongation at break are 438.92%, ash content=31.85% and acid absorbed =7.85%.