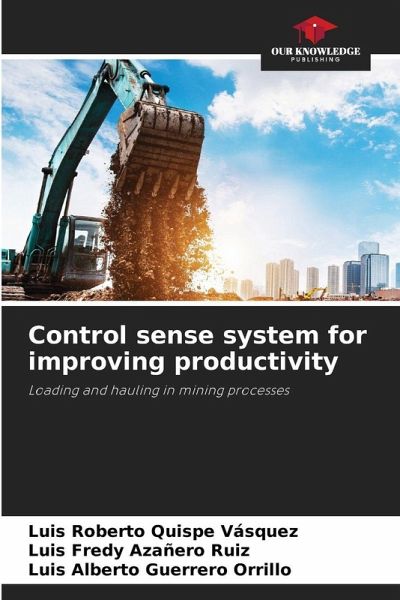

Control sense system for improving productivity

Loading and hauling in mining processes

Versandkostenfrei!

Versandfertig in 6-10 Tagen

40,99 €

inkl. MwSt.

PAYBACK Punkte

20 °P sammeln!

The methods used were the Ishikawa diagram, Pareto diagram and PHVA methodology, the instruments used were the interview and the summary sheet. Compared to other studies, the present study has considered the implementation of fuel sensors, fatigue control, load tonnage and tire pressure. The improvement in the productivity of the loading and hauling process was reflected in the increase of the indicators of instantaneous productivity for CAT 374 increased 352.20 Ton/hour, for CAT390 is 284; the operational productivity for CAT 374 increased 42.38 and for CAT390 increased 32.59; the effective p...

The methods used were the Ishikawa diagram, Pareto diagram and PHVA methodology, the instruments used were the interview and the summary sheet. Compared to other studies, the present study has considered the implementation of fuel sensors, fatigue control, load tonnage and tire pressure. The improvement in the productivity of the loading and hauling process was reflected in the increase of the indicators of instantaneous productivity for CAT 374 increased 352.20 Ton/hour, for CAT390 is 284; the operational productivity for CAT 374 increased 42.38 and for CAT390 increased 32.59; the effective productivity for CAT374 increased 49.25 and for CAT390 54.75; the Hang for CAT374 and CAT390 reduced 2.63%; the usage for CAT 390 increased 0.95% and for CAT390 is 2.64%; the UoA indicator for CAT390 increased 3.61% and for CAT374 increased 6.49%; the utilization for CAT390 increased 2.73% and for CAT374 increased 6.17%; as for the hauling indicators queue for the hauling fleet decreased 6.87%, utilization for scania460 decreased 0.08% and for Scania 460HT decreased 1.34%; for Scania 460 increased 0.82% .