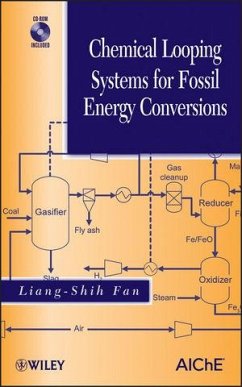

This book presents the current carbonaceous fuel conversion technologies based on chemical looping concepts in the context of traditional or conventional technologies. The key features of the chemical looping processes, their ability to generate a sequestration-ready CO2 stream, are thoroughly discussed. Chapter 2 is devoted entirely to the performance of particles in chemical looping technology and covers the subjects of solid particle design, synthesis, properties, and reactive characteristics. The looping processes can be applied for combustion and/or gasification of carbon-based material such as coal, natural gas, petroleum coke, and biomass directly or indirectly for steam, syngas, hydrogen, chemicals, electricity, and liquid fuels production. Details of the energy conversion efficiency and the economics of these looping processes for combustion and gasification applications in contrast to those of the conventional processes are given in Chapters 3, 4, and 5.Finally, Chapter 6 presents additional chemical looping applications that are potentially beneficial, including those for H2 storage and onboard H2 production, CO2 capture in combustion flue gas, power generation using fuel cell, steam-methane reforming, tar sand digestion, and chemicals and liquid fuel production. A CD is appended to this book that contains the chemical looping simulation files and the simulation results based on the ASPEN Plus software for such reactors as gasifier, reducer, oxidizer and combustor, and for such processes as conventional gasification processes, Syngas Chemical Looping Process, Calcium Looping Process, and Carbonation-Calcination Reaction (CCR) Process. Note: CD-ROM/DVD and other supplementary materials are not included as part of eBook file.

Dieser Download kann aus rechtlichen Gründen nur mit Rechnungsadresse in A, B, BG, CY, CZ, D, DK, EW, E, FIN, F, GR, HR, H, IRL, I, LT, L, LR, M, NL, PL, P, R, S, SLO, SK ausgeliefert werden.